HONY®Nylon 6 is also a commonly used material in precision machining. It is often used to process small precision fixtures. Due to the hardness, toughness and processing characteristics of nylon materials, it plays an irreplaceable role in the processing of precision parts. HONY®MC Nylon (Nylon) polyamide, English name Polyamide (abbreviated as PA), density 1.16g/cm3, is the main chain of molecules containing repeated amide groups - [NHCO]- thermoplastic resins in general, including aliphatic PA, aliphatic - aromatic PA and aromatic PA. aliphatic PA variety, production, widely used, its name by the synthesis of monomer specific The name is determined by the specific number of carbon atoms in the synthesis monomer. Features of PA6 processing part PA gears: Benefits Of Machining Nylon Polyamide: High amount of insulation and resistance to corrosion, impact, and abrasion. Nylon is lighter, stronger and offers high wear resistance, providing longer-wearing machined parts that require less maintenance than metal. Nylon is ideal for the production of fire-resistant items since it melts NOT burn. High tensile strength and elasticity modulus. Types Of Milling PA6 6 Nylon: Fittings Bushings Rivets Washers Threaded components PA gears,PA PA6 processing part,Machining Nylon Polyamide,Milling PA6 6 Nylon,PA6 Screw Machine Parts,PA6 processing part,CNC PA6 component Hony Engineering Plastics Limited , https://www.honyplastic.com

Diameter

FLOW

PRESSURE

FLOW

PRESSURE

FLOW

PRESSURE

FLOW

PRESSURE

FLOW

PRESSURE

FLOW

PRESSURE

FLOW

PRESSURE

3D140 220kW

mm

m³/h

MPa

m³/h

MPa

m³/h

MPa

m³/h

MPa

m³/h

MPa

m³/h

MPa

m³/h

MPa

Lianyungang Landmark Co., Ltd was established in 1992. In 2006, we built our factory, Tianjin Jingcheng High-Pressure Pump Manufacturing Co., Ltd, which focuses on the research and manufacturing of ultra-high pressure pumps and cleaning machines. With the business philosophy of "credit is the basis, quality is the first," we continuously research and design exquisite equipment to earn the trust of both old and new customers and develop together with all of them.

We invested over 80 million RMB for the construction of our factory in the "Bohai Economic Center," located at Jinnan Shuanggang Industrial Park. The factory covers an area of 8,000 square meters, and we also invested more than 10 million RMB to purchase a number of high-precision CNC lathes, milling machines, grinders, boring machines, and other advanced production equipment. Our workforce includes nearly 100 high-quality employees, with two-thirds being senior technical and management staff.

As a high-tech enterprise, our company integrates research, production, sales, and service, and has always been committed to technological innovation and R&D of high-pressure reciprocating piston pumps and high-pressure water jet equipment. We also collaborate with well-known international companies to adopt high-end technology and international standards, developing a series of high-pressure pumps used across various industries such as petroleum, coal, chemicals, electric power, machinery, metallurgy, food, pharmaceuticals, textiles, and descaling hot-rolled steel. We can also provide customers with customized high-pressure pump solutions and high-pressure water jet cleaning technology consulting services.

Our pump series products and complete cleaning equipment sets have been widely praised by users, known for their "International quality" and "Domestic price." After years of development, we successfully built the brand "Jingcheng" from Tianjin to China and beyond. Our high-pressure pumps and water jetting equipment have passed ISO9001 quality management system certification, health, safety, and environmental management system certification, and mining product safety certification, among others. Through the continuous efforts of our R&D department, we have obtained national patents, giving us unique technical advantages and strong brand competitiveness, making us more competitive in the market.

We are very grateful to all pump and cleaner users at home and abroad for your support and trust over the years. We will continue to provide quality products and excellent service.

Factory:

JinCheng pumping systems offer an effective, efficient, and reliable solution for your high-pressure water needs.

Welcome to visit our factory!

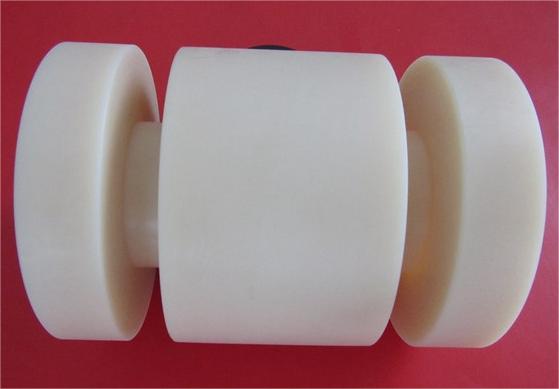

Nylon products are widely used, is a good material for plastic instead of steel, iron, copper and other metals, is important is MC cast nylon instead of wear-resistant parts of machinery and equipment, instead of copper and alloy for wear-resistant parts of equipment. Suitable for making wear-resistant parts, transmission structure parts, conveying sliding parts, automobile manufacturing parts, chemical machinery parts, chemical equipment and other parts. Such as gears, rollers and casters, bushings, skids and pulleys, impellers, conveyor rollers, structural connectors, sealing rings and gaskets, screws and nuts, etc.

1. High strength, able to bear the load for a long time.

2. Good resilience, able to bend without deformation, while maintaining toughness, resisting repeated impact.

3. Wear-resistant self-lubricating, providing better than bronze cast iron carbon steel and phenolic laminate in oil-free (or de-oiled) lubrication applications, reducing consumption and saving energy.

4. Noise absorption, vibration damping, MC nylon modulus is much smaller than metal, the attenuation of vibration is large, providing a practical way to prevent noise better than metal.

5. Compared with metal, MC nylon hardness is low and does not damage to the wear parts.

6. Continuously withstand the working temperature of -40~100℃

HONY®MC Nylon including :

Nylon 6

Outstanding toughness, temperature resistance -40-110 degrees, excellent wear resistance, slightly worse dimensional stability, moderate price, mostly used for one-time injection molding.

Nylon 66

Toughness and strength are outstanding, temperature resistance -50-130 degrees, excellent wear resistance, general dimensional stability, higher price, mostly used for one-time injection molding

MC nylon

Toughness and strength are outstanding, temperature resistance -40-110 degrees, excellent wear resistance, general dimensional stability, moderate price, the product is mostly made of rods, tubes, plates profiles, single product can be a few grams to hundreds of kilograms.

Change the name of nylon

1. Glass fiber reinforced nylon: increased strength, reduced toughness, increased temperature resistance.

2. Carbon fiber reinforced nylon: strength increased to the limit of nylon, slightly lower toughness, temperature resistance increased to the limit of nylon.

3. Molybdenum disulfide self-lubricating wear-resistant nylon: reduce the coefficient of friction and improve the wear resistance of the product.

4. Oil-containing self-lubricating wear-resistant nylon: reduce the coefficient of friction and improve the wear resistance of the product.

5. Low temperature resistant toughened nylon: increase the toughening agent proportionally to improve the toughness of the product, so that it will not be brittle in low temperature environment.

6. High temperature resistant nylon: the highest use temperature can reach 260 degrees.

Nylon has good comprehensive properties, including mechanical properties, heat resistance, wear resistance, chemical resistance and self-lubrication, and has a low coefficient of friction, has certain flame retardancy, and is easy to process. It is suitable for glass fiber and Other fillers are filled and modified to improve performance and expand application range.

Due to its non-toxic, light weight, excellent mechanical strength, wear resistance and good corrosion resistance, nylon is widely used to replace copper and other metals in the manufacture of bearings, gears and pumps in machinery, chemical industry, instrumentation, automobile and other industries. leaves and other parts. Polyamide has high strength after melt spinning and is mainly used as synthetic fiber and as medical suture.

Corrosion resistance: Nylon has very good chemical stability and is very stable to almost any chemical reagent, even at higher temperatures, it can still maintain good chemical stability. In addition, it is also resistant to hot water and steam. It can be used for a long time in the steam of 200~250 ℃.

Heat resistance: Nylon has a higher melting point, generally above 240°C. The heat resistance of aromatic nylon is higher than that of aliphatic nylon. If certain reinforcing fillers are added, its thermal stability will be greatly improved, and the heat distortion temperature can be as high as 250 ℃.

PA6 Screw Machine Parts Solvent resistance: Nylon has good chemical stability, alkali resistance, and weak acid resistance; it is also a solvent-resistant plastic, especially resistant to aromatic compounds and common organic solvents, and can be used in chemical and chemical instruments; in environments where certain metals are prone to rust , such as water meters, can be replaced by nylon materials.

High Quality Industrial 8000psi High Pressure Water Pump Price (FJ0130)

Model NO.: 8000PSI High Pressure Water Pump (FJ0130)

Flow Rate: 15 - 530 L/M, 3.7-140.2 GPM

Size: 2.6*1.5*1.7 m³, and customizable

Power: Hydraulic

Max Input Power: 90-500 kW

Stroke: Internal Deceleration

Theory: Plunger Pump, Piston Pump

Plunger Diameter: 14.3mm-52mm

Accessories: Gauges, High Pressure Fittings, High Pressure Hose

Trademark: JINGCHENG

Transport Package: Container: 3500*1800*2200 mm

Specification: CE; ISO9001; WJTA

Origin: Tianjin

HS Code: 84243000

Our high-pressure water pumping systems are suitable for a wide range of applications that require high or ultra-high pressure water streams:

Â

Cleaning

Jetting

Blasting

Cutting

Â

JinCheng Pumping systems are widely used in many industries, including:

Â

Construction

Manufacturing

Mining

Oil Field Service

Industrial Cleaning

Â

We offer a variety of optional features for our diesel and electric pumping systems. Customize the system according to your specific application. Options include:

Â

Power options

Control Panels

Motor Control

Pressure Gauges

Rupture Disc Assembly

Relief Valve

Suction Supply

Noise Dampening

Tow Bar (on base)

Paint Color

Â

The Advanced Design ("AD") philosophy of JinCheng's team is reflected in our diesel and electric pumping systems. These systems use proven technology to create a simple, easy-to-maintain high-pressure pump with fewer dynamic liquid-end parts than any other power pump currently available on the market.