STKM11A is a Japanese Industrial Standard (JIS) classification of carbon steel tubes used for general structural purposes. Its chemical composition plays a vital role in determining its mechanical properties and overall performance in various applications.

Table of contents

- STKM11A chemical composition

- JIS G3445 Grade STKM11A mechanical properties

- STKM11A equivalent material

- Flattening and Bending of ASTM A519 MT1010

- Physical properties of grade STKM11A

- Tolerances of JIS G3445 STKM11A tube

- Chemical compatibility of STKM11A material

- ASTM Standards of Grade 11A

- Range of products of MT1010

- Delivery Condition of DIN 1.0034

- STKM11A hardness

- Smelting temperature of ASTM A519 MT1010

- JIS G3445 Gr STKM11A Thermal Properties

- Cold finishing temperature of Grade 11A

- Creep strength of MT1010 material

- STKM 11A grade working temperature range

- EN 1.0034 testing methods

- STKM 11A JIS G3445 Heat treatment techniques

- STKM11A Carbon Steel Tubes Inspection Report

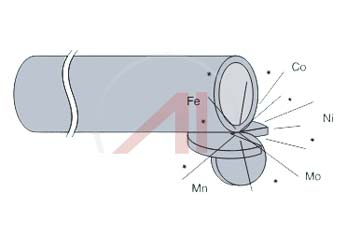

STKM11A Chemical Composition

JIS G3445 Grade STKM11A Mechanical Properties

Elongation

A (%) |

Yield Strength

Rp0.2 (MPa) |

Tensile Strength

Rm (MPa) |

Impact

KV (J) |

Reduction in cross section on fracture

Z (%) |

| 13 |

518 (≥) |

424 (≥) |

34 |

23 |

Grade 11A manufactured using hot or cold finish techniques, refer to JIS G3445 STKM11A steel equivalents

STKM11A tubes are produced through continuous manufacturing processes, either by hot or cold finishing. Hot finishing involves rolling at high temperatures, while cold finishing is done at room temperature. Pipes with diameters above 38mm typically use hot finishing, whereas smaller diameter pipes benefit from cold finishing for better dimensional accuracy and surface finish.

STKM11A Equivalent Material

| NUMBER |

GRADE |

ASTM NUMBER |

JIS |

MECHANICAL |

| D 3517 |

Grade 11 A |

STKM 11 A |

A513 |

G-3445 |

MT1010 |

Flattening and Bending of ASTM A519 MT1010

| Flattening Test |

Bending Test |

Distance

between

that parts

(D=OD) |

Bend

Angle |

Inside

Radius

(D=OD) |

| 1/2D |

180° |

4D |

STKM11A grade contains 0.40% silicon, view physical properties of STKM11A steel pipe

Its high density offers a balance between strength and weight, making it ideal for applications requiring robustness and durability. Despite its weight, the strength-to-weight ratio is favorable, allowing it to perform well in high-temperature environments.

Physical Properties of Grade STKM11A

Density

kg/dm3 |

Thermal conductivity

W/mK |

Temperature T

°C/F |

Specific heat

J / kgK |

| 371 (≥) |

13 |

34 |

41 |

Tolerances of JIS G3445 STKM11A Tube

| Wall Thickness (WT) |

Tolerances on Wall Thickness (WT) |

| Under 4mm |

+0.6 -0.5 |

| 4mm or over |

+15% -12.5% |

| Under 3mm |

±0.3 |

| 3mm or over |

±10% |

| Under 2mm |

±0.15 |

| 2mm or over |

±8% |

Chemical Compatibility of STKM11A Material

| Media |

Symbol |

Compatibility |

| Acetonitrile (Methyl Cyanide) |

|

Excellent |

| Acetyl Chloride |

|

Good |

| Adipic Acid |

|

Excellent |

| Alcohol: Isobutyl |

|

Good |

| Allyl Bromide |

|

Not recommended |

| Amyl Acetate (Banana Oil) |

|

Fair to Poor |

| Butyric Acid |

|

Not recommended |

ASTM Standards of Grade 11A

| Standard |

| ASTM A519 |

ASTM A513 |

Range of Products of MT1010

| Products |

Dimension |

Processes |

| Seamless and Welded Pipes/Tubes |

OD:6-219mm x WT:0.5-20.0mm |

Welded, Hot extrusion, Cold Drawn |

| Plates / Sheets |

0.08-200mm(T)*W*L |

Forging, cold and hot rolling |

| Round Bar |

Φ8-1200mm*L |

Cast, Forging, cold and hot rolling |

| Coil / Strip |

0.03-16.0x1200mm |

Hot-Rolled & Cold-Rolled |

Delivery Condition of DIN 1.0034

| Designation |

Symbol |

| Cold finished (soft) |

BKW |

| Cold finished (hard) |

BK |

| Cold finished and stress-relieved |

BKS |

| Normalized |

NBK |

| Annealed |

GBK |

STKM11A material is widely used in the automobile industry, refer to hardness of STKM 11A JIS G3445 grade

It is commonly used in the automotive industry due to its high hardness, which results from its chemical composition and the manufacturing process it undergoes. This combination makes it suitable for automotive applications where high hardness, strength, and durability are required to withstand pressure and impact.

STKM11A Hardness

Smelting Temperature of ASTM A519 MT1010

| Smelting temperature |

1821°C – 1823°C |

DIN 1.0034 melting range is 1480 – 1526 °C, check ASTM A519 MT1010 material thermal properties

The thermal conductivity of STKM11A is moderate, making it efficient for heat transfer. This property makes it suitable for use in automotive exhaust systems and heat exchangers within the specified temperature range.

JIS G3445 Gr STKM11A Thermal Properties

| Temperature (°C) |

14 |

314 |

937 |

| Modulus of elasticity (GPa) |

– |

281 |

– |

| Mean coefficient of thermal expaion ×10-6/(°C) |

– |

– |

13 |

| Thermal conductivity (W/m·°C) |

– |

31.3 |

42.2 |

| Specific thermal capacity (J/kg·°C) |

– |

111 |

– |

| Specific electrical resistivity (Ω mm²/m) |

0.33 |

– |

– |

| Deity (kg/dm³) |

– |

– |

443 |

| Poisson’s coefficient, ν |

– |

– |

124 |

Cold Finishing Temperature of Grade 11A

| Temperature |

1200°F [650°C] |

View creep strength and temperature range of STKM11A carbon steel material

The creep strength and rupture properties depend mainly on its chemical composition and microstructure. It can operate in low to moderate temperatures, so it's advisable to follow the given temperature range to ensure the product's longevity and performance.

Creep Strength of MT1010 Material

Creep strain

(10000h)

(Rp1,0) N/mm2 |

Creep rupture

(10000h)

(Rp1,0) N/mm2 |

| 141 |

922 |

STKM 11A Grade Working Temperature Range

| Temperature range |

425 °C |

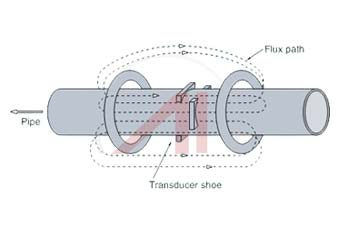

EN 1.0034 Testing Methods

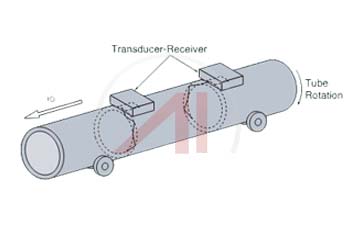

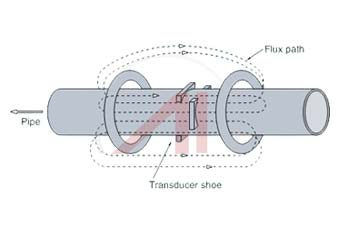

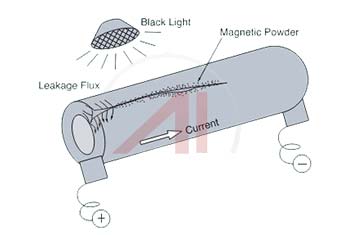

Ultrasonic Inspection

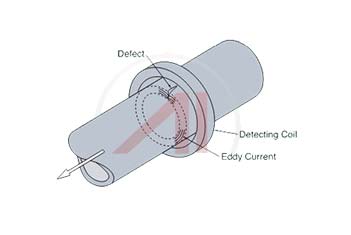

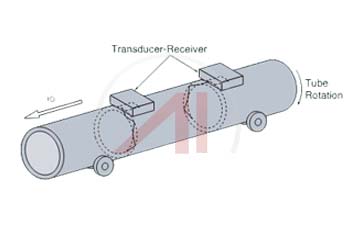

Eddy Current Inspection

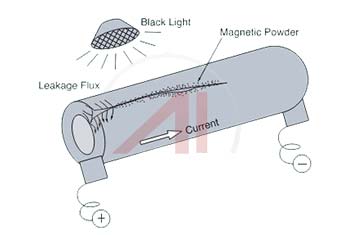

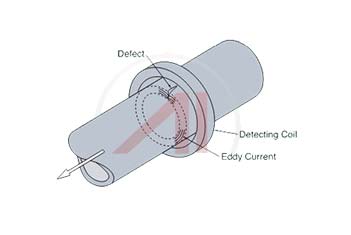

Magnetic Particle Inspection

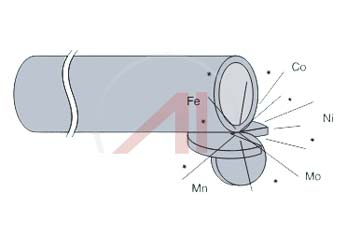

Spectro-Chemical Analysis

Electromagnetic Inspection

STKM 11A JIS G3445 Heat Treatment Techniques

| Annealing |

Quenching |

Tempering |

Normalizing |

Q & T |

| √ |

√ |

√ |

√ |

√ |

STKM11A Carbon Steel Tubes Inspection Report

OD.

(mm) |

Tolerance

(mm) |

ID.

(mm) |

Tolerance

(mm) |

Length

(mm) |

Tolerance

(mm) |

Straightness

(mm) |

| 4 |

±0.05 |

1.5 |

-0/+20 |

3000 |

±0.05 |

1:1000 |

Electric Actuated Ball Valve

Electric Actuated Ball Valve,Metal Seat Ball Valve,Electric Actuator Ball Valve,Electric Actuated Floating Ball Valve

RST VALVE GROUP CO.,LTD , https://www.stainlesssteel-valves.com